Description

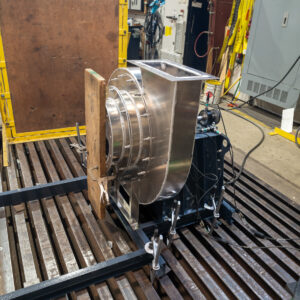

3 HP Explosion Proof Motor – Baldor TEFC motor rated for hazardous locations

Arrangement 1 – Belt drive configuration provides flexible speed options

AMCA A Spark Resistant Construction – Engineered to minimize ignition risks in combustible dust applications

Full Aluminum Construction – Complete airstream, wheel, inlet box, and dampers in aluminum for lightweight durability

Aluminum Inlet Vane Damper – Provides precise flow control and energy management

Aluminum Opposed Blade Outlet Damper – System balancing and shut-off capability

Inlet and Outlet Flex Connectors with Aluminum Liners – Vibration isolation at both connections with material-matched liners

Unitary Base with Rubber Pad Vibration Isolators – Integrated mounting with vibration isolation for quiet operation

100,000 Hour L-10 Bearings – Extended bearing life with accessible lube lines reduces maintenance frequency

These fans deliver dependable performance in pneumatic conveying and material handling applications requiring spark resistant construction.